LOCATION: EMEA

Technical Hub

FAQs & Instructional Videos

Typically asphalt, however concrete is used in runways and high jump areas

Asphalt requires a minimum of 14 days, with sufficient sun exposure and rain, to burn off surface oils. Concrete is a minimum of 30 days, and needs to be assessed for moisture content, before application.

Rekortan has many different tracks systems, to meet both performance and budget.

The Rekortan tracks are made from a combination of high-quality polyurethanes (manufactured by our ISO Certified company — APT) and combined with both SBR (recycled rubber granules) and EPDM high quality synthetic rubber granules (manufactured by our ISO Certified company — Melos).

WA stands for World Athletics and is the governing body for international track and field performances requirements. A WA certificate indicates that the track system has been tested at an independent test facility and passed all the high standards for track surfacing performance.

Rekortan has the Rekortan B, and BS systems that are permeable, and the Rekortan BSS, M, M99, G10, and G13 that are impermeable.

Structural spray textures are achieved by a mix of the polyurethane resin and the epdm granules and spray applied to create the final texture and color of the track. The embedded surface is achieved with a fluid application of the polyurethane track resin, and the epdm granules are broadcast / seeded into the liquid, and when set creates the final texture and color of the track.

The solvent sprays have been in the market for many years and have performed well. However, due regulations and innovations, the Water Based Structural Sprays now are the preferred material. The advantages, little or no smell, less overspray, faster dry times, easier to clean up and dispose of (non — Haz), and more UV stable (longer color protection)

For the construction of a new track, it is 5 years.

This always depends on the system selected and the use and maintenance of track, but typically a polyurethane track surface will last 8-10 years, and then in most cases can be resurfaced to add additional years of service.

First, Track lines should only be applied by an experienced track striper. The track paints shall be approved by the striper or manufacturer. Rekortan manufactures a Water Based PU line paint.

ASBA position is that one coat of a high-quality paint, applied by an experienced striper, is recommended.

If the existing surface is sound — not delaminating, no major cracking or peeling, and based on an inspection by an experience track contractor, yes they can. Many old tracks are successfully resurfaced every year.

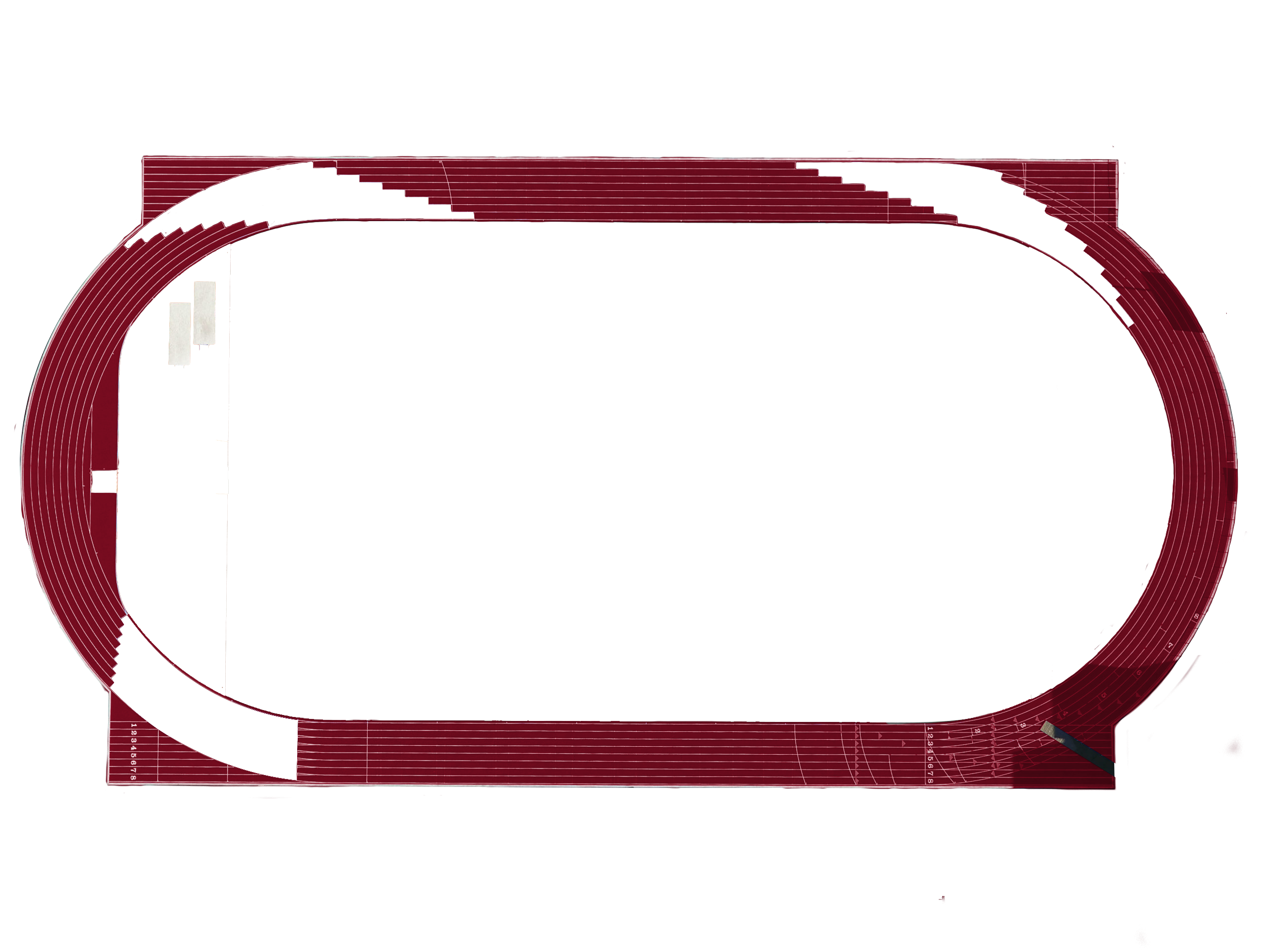

- Track

- Track Lanes

- Exchange Zones

- Side Zones

- Jump Lane